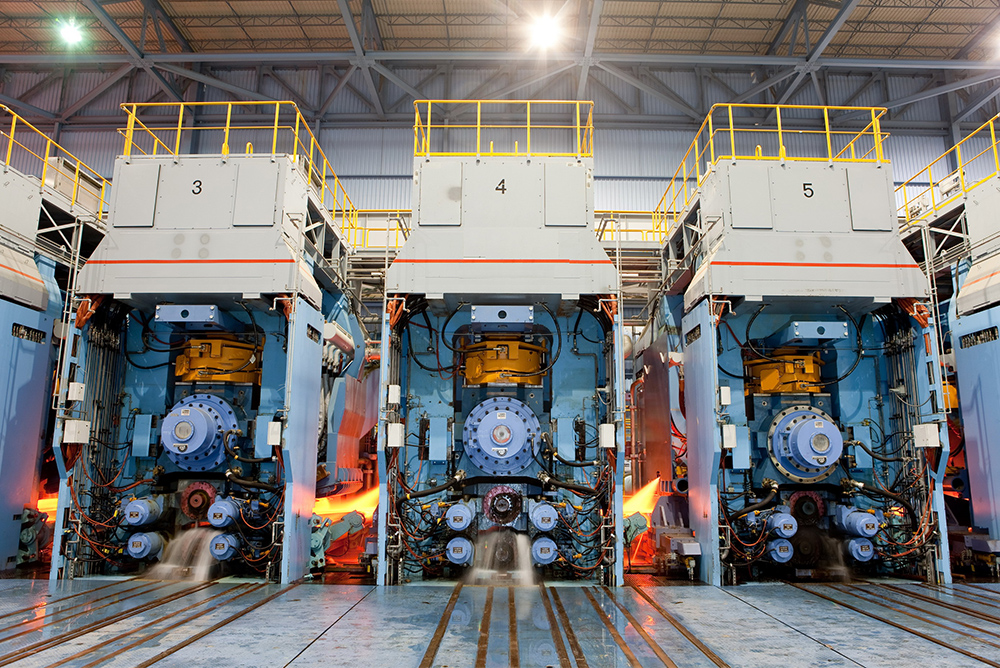

Because the roller bearing on the rolling mill bears very large radial load, to bear such a large force on the roll neck of the roller it is required that the larger the diameter of the roll neck the better. Meanwhile the outer diameter should not be larger than the difference between the roll body of the roller and the largest spend that the roll body permits. The load ability of the bearing should be improved based on the width installation position so the roller bearing often adopts multi-row bearing.

On the principal of matching when the inner ring of rolling bearing revolves it should be integrated tightly with the revolving shaft. If loose matching is adopted sliding will occur between the inner ring and the roll neck thus the matching surface will be damaged. Breaking or locking will occur on the axis. The inner ring will be broken if slight break occurs on its surface when the inner ring is being quenched. These kinds of accidents will happen more frequently when the working speed is higher. But for roll neck bearing because the roll surface should be often grinded the bearing should be disassembled when the roller is to be grinded. For installation and disassembly ease loose matching should be adopted for Self-aligning Roller Bearing and Four-row Tapered Roller Bearing. To reduce sliding abrasion on the surfaces of the inner ring and roll neck Four-row Tapered Roller Bearing with spiral groove on the inner ring. It is testified by practice that lubrication both by dry oil and thin oil can be applied on the Four-row Tapered Roller Bearing. Lubrication oil supplied on the rolling surface of the bearing flows into the bearing through oil groove designed on the side of the inner ring. It moves and is distributed on the roll neck of the roller and can effectively reduce the sliding abrasion on the inner ring.

For Four-row Cylindrical Roller Bearing because the inner ring and the outer ring components with cage are separable the inner ring can be tightly matched with the roll neck. For rolling mill whose roller is grinded frequently and should be changed often the inner ring must be matched with the outer ring components from different factories.

Address:No. 436, Longmen Avenue, Luolong District, Luoyang City, Henan Province, China

Tel:+86-13837910731 E-mail: sale@lyefinebearing.com Wechat : +86-13837910731