|

Dimensions |

Basic load ratings |

Designations |

Calculated constant |

Load factors |

Mass |

Limiting speeds |

|||||||||||||||

|

mm |

kN |

e |

Y |

Y0 |

kg |

r/min |

|||||||||||||||

|

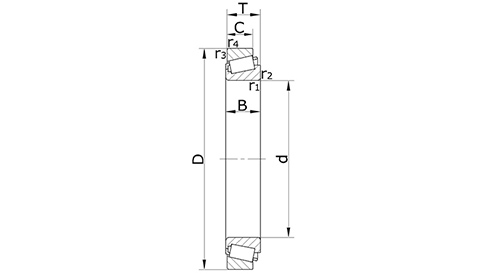

d |

D |

T |

B |

C |

r1、2min |

r3、4min |

Cr |

Cor |

fat |

oil |

|||||||||||

|

152.400 |

222.250 |

46.830 |

46.83 |

34.925 |

3.5 |

1.5 |

330 |

630 |

M231649/M231610 |

0.33 |

1.8 |

1 |

5.80 |

1500 |

2000 |

||||||

|

|

254.000 |

66.675 |

66.675 |

47.625 |

7.0 |

3.3 |

583 |

980 |

99600/99100 |

0.40 |

1.5 |

0.8 |

12.5 |

1300 |

1800 |

||||||

|

155.575 |

336.550 |

85.725 |

79.45 |

54.03 |

6.4 |

6.4 |

825 |

1200 |

BT1B328833 |

0.79 |

0.76 |

0.4 |

33.5 |

900 |

1300 |

||||||

|

158.750 |

205.583 |

23.812 |

23.812 |

18.258 |

4.8 |

1.5 |

138 |

280 |

L432348/L432310 |

0.37 |

1.6 |

0.9 |

1.90 |

1500 |

2000 |

||||||

|

|

225.425 |

41.275 |

39.688 |

33.338 |

3.5 |

3.3 |

264 |

585 |

46780/46720 |

0.37 |

1.6 |

0.9 |

5.30 |

1400 |

1900 |

||||||

|

160 |

252.412 |

63.500 |

69.93 |

52.46 |

1.5 |

3.3 |

512 |

900 |

BT1B443924 |

0.26 |

2.3 |

1.3 |

11.7 |

1300 |

1800 |

||||||

|

165.100 |

225.425 |

41.275 |

39.688 |

33.338 |

3.5 |

3.3 |

264 |

585 |

46790/46720 |

0.37 |

1.6 |

0.9 |

4.75 |

1400 |

1900 |

||||||

|

|

336.500 |

92.075 |

92.25 |

69.85 |

3.3 |

6.4 |

1120 |

1700 |

HH437549/HH437510 |

0.37 |

1.6 |

0.9 |

37.0 |

950 |

1400 |

||||||

|

177.800 |

227.012 |

30.162 |

30.162 |

23.02 |

1.5 |

1.5 |

187 |

425 |

36990/36920 |

0.44 |

1.35 |

- |

2.95 |

1300 |

1800 |

||||||

|

|

260.350 |

53.975 |

53.975 |

41.275 |

3.5 |

3.3 |

484 |

900 |

M236849/M236810 |

0.33 |

1.8 |

1 |

9.35 |

1200 |

1700 |

||||||

|

178.595 |

265.112 |

51.595 |

57.15 |

38.895 |

3.3 |

3.3 |

495 |

880 |

M336948/M336912 |

0.33 |

1.8 |

1 |

9.60 |

1200 |

1700 |

||||||

|

179.934 |

265.112 |

51.595 |

57.15 |

38.895 |

3.3 |

3.3 |

495 |

880 |

M336949/M336912 |

0.33 |

1.8 |

1 |

9.40 |

1200 |

1700 |

||||||

|

184.150 |

266.700 |

47.625 |

46.833 |

38.1 |

3.5 |

3.3 |

374 |

800 |

67883/67820 |

0.48 |

1.25 |

0.7 |

8.20 |

1100 |

1600 |

||||||

|

187.325 |

269.875 |

55.562 |

55.562 |

42.862 |

3.5 |

3.3 |

473 |

950 |

M238849/M238810 |

0.33 |

1.8 |

1 |

9.85 |

1100 |

1600 |

||||||

|

|

282.575 |

50.800 |

47.625 |

36.512 |

3.5 |

3.3 |

402 |

695 |

87737/87111 |

0.43 |

1.4 |

0.8 |

9.80 |

1100 |

1600 |

||||||

|

189.738 |

279.400 |

52.388 |

57.15 |

41.275 |

3.3 |

3.3 |

523 |

980 |

M239447/M239410 |

0.33 |

1.8 |

1 |

11.0 |

1100 |

1600 |

||||||

|

190.475 |

279.400 |

52.388 |

57.15 |

41.275 |

3.3 |

3.3 |

523 |

980 |

M239449/M239410 |

0.33 |

1.8 |

1 |

11.0 |

1100 |

1600 |

||||||

|

190.500 |

266.700 |

47.625 |

46.833 |

38.1 |

3.5 |

3.3 |

374 |

800 |

67885/67820 |

0.48 |

1.25 |

0.7 |

8.20 |

1100 |

1600 |

||||||

|

|

282.575 |

50.800 |

47.625 |

36.512 |

3.5 |

3.3 |

402 |

695 |

87750/87111 |

0.43 |

1.4 |

0.8 |

9.60 |

1100 |

1600 |

||||||

|

191.237 |

279.400 |

53.975 |

58.738 |

41.275 |

3.3 |

3.3 |

523 |

980 |

M239448A/M239410 |

0.33 |

1.8 |

1 |

10.5 |

1100 |

1600 |

||||||

|

196.850 |

257.175 |

39.688 |

39.688 |

30.162 |

3.5 |

3.3 |

275 |

655 |

LM739749/LM739710 |

0.44 |

1.35 |

0.8 |

5.40 |

1100 |

1600 |

||||||

|

200.025 |

276.225 |

42.862 |

46.038 |

34.133 |

3.5 |

3.3 |

391 |

780 |

LM241147/LM241110 |

0.31 |

1.9 |

1.1 |

7.70 |

1000 |

1500 |

||||||

|

203.200 |

261.142 |

28.575 |

27.783 |

21.433 |

1.5 |

1.5 |

216 |

440 |

LL641149/LL641110 |

0.40 |

1.5 |

0.8 |

3.75 |

1100 |

1600 |

||||||

|

|

282.575 |

46.038 |

46.038 |

36.512 |

3.5 |

3.3 |

380 |

830 |

67983/67920 |

0.50 |

1.2 |

0.7 |

8.95 |

1000 |

1500 |

||||||

|

203.987 |

276.225 |

42.662 |

46.038 |

34.133 |

3.5 |

3.3 |

391 |

780 |

LM241148/LM241110 |

0.31 |

1.9 |

1.1 |

7.25 |

1000 |

1500 |

||||||

| Dimensions | Basic load | Designations | Calculated constant | Load | Mass | Limiting | |||||||||||||||

| ratings | factors | speeds | |||||||||||||||||||

| mm | kN | e | Y | Y0 | kg | r/min | |||||||||||||||

| d | D | T | B | C | r1、2min | r3、4min | Cr | Cor | fat | oil | |||||||||||

| 206.375 | 282.575 | 46.038 | 46.038 | 36.512 | 3.5 | 3.3 | 380 | 830 | 67985/67920 | 0.5 | 1.2 | 0.7 | 8.6 | 1000 | 1500 | ||||||

| 336.55 | 98.425 | 100.012 | 77.788 | 3.3 | 3.3 | 1140 | 2160 | H242649/H242610 | 0.33 | 1.8 | 1 | 34 | 900 | 1300 | |||||||

| 212.725 | 285.75 | 46.038 | 46.038 | 34.925 | 3.5 | 3.3 | 352 | 780 | LM742745/LM742710 | 0.48 | 1.25 | 0.7 | 8 | 1000 | 1500 | ||||||

| 215.9 | 285.75 | 46.038 | 46.038 | 34.925 | 3.5 | 3.3 | 352 | 780 | LM742749/LM742710 | 0.48 | 1.25 | 0.7 | 7.9 | 1000 | 1500 | ||||||

| 216.408 | 285.75 | 46.038 | 49.212 | 34.925 | 3.5 | 3.3 | 352 | 780 | LM742747/LM742710 | 0.48 | 1.25 | 0.7 | 7.85 | 1000 | 1500 | ||||||

| 285.75 | 46.038 | 49.29 | 35 | 3.5 | 3.3 | 330 | 695 | BT1B443786AB | 0.48 | 1.25 | 0.7 | 7.85 | 1000 | 1500 | |||||||

| 216.713 | 285.75 | 46.038 | 49.212 | 34.925 | 3.5 | 3.3 | 352 | 780 | LM742747A/LM742710 | 0.48 | 1.25 | 0.7 | 7.8 | 1000 | 1500 | ||||||

| 220.116 | 317.5 | 47.625 | 52.338 | 36.512 | 3.3 | 3.3 | 523 | 980 | LM245832/LM245810 | 0.31 | 1.9 | 1.1 | 12.5 | 900 | 1300 | ||||||

| 220.878 | 317.5 | 47.625 | 52.338 | 36.512 | 3.3 | 3.3 | 523 | 980 | LM245833/LM245810 | 0.31 | 1.9 | 1.1 | 12.5 | 900 | 1300 | ||||||

| 230.188 | 317.5 | 47.625 | 52.338 | 36.512 | 3.3 | 3.3 | 523 | 980 | LM245846/LM245810 | 0.31 | 1.9 | 1.1 | 11 | 900 | 1300 | ||||||

| 231.775 | 317.5 | 47.625 | 52.338 | 36.512 | 3.3 | 3.3 | 523 | 980 | LM245848/LM245810 | 0.31 | 1.9 | 1.1 | 10.5 | 900 | 1300 | ||||||

| 247.65 | 406.4 | 115.888 | 117.475 | 93.662 | 6.4 | 6.4 | 1610 | 3150 | HH249949/HH249910 | 0.33 | 1.8 | 1 | 60 | 800 | 1100 | ||||||

| 255.625 | 342.945 | 57.15 | 62.08 | 44.5 | 6.4 | 3.3 | 660 | 1400 | BT1B417708 | 0.35 | 1.7 | 0.9 | 14 | 850 | 1200 | ||||||

| 257.175 | 342.9 | 57.15 | 57.15 | 44.45 | 6.4 | 3.3 | 660 | 1400 | M349549/M349510 | 0.35 | 1.7 | 0.9 | 14 | 850 | 1200 | ||||||

| 263.525 | 325.438 | 28.575 | 28.575 | 25.4 | 1.5 | 1.5 | 220 | 550 | 38880/38820 | 0.37 | 1.6 | 0.9 | 53 | 900 | 1300 | ||||||

| 266.56 | 325.438 | 29.5 | 33.47 | 25.48 | 1 | 1.5 | 209 | 475 | BT1B446356A | 0.37 | 1.6 | 0.9 | 5.1 | 900 | 1300 | ||||||

| 266.7 | 325.438 | 27.755 | 31.88 | 25.48 | 1.5 | 1.5 | 209 | 475 | BT1B443884AE | 0.37 | 1.6 | 0.9 | 5.1 | 900 | 1300 | ||||||

| 355.6 | 57.15 | 57.15 | 44.45 | 3.5 | 3.3 | 644 | 1400 | LM451349/LM451310 | 0.35 | 1.7 | 0.9 | 15.5 | 850 | 1200 | |||||||

| 292.1 | 374.65 | 47.625 | 47.625 | 34.925 | 3.5 | 3.3 | 501 | 1140 | L555249/L555210 | 0.4 | 1.5 | 0.8 | 12 | 800 | 1100 | ||||||

| 300 | 495.3 | 141.288 | 141.288 | 114.3 | 6.4 | 6.4 | 2330 | 4550 | HH258248/HH258210 | 0.33 | 1.8 | 1 | 107 | 630 | 850 | ||||||

| 304.8 | 546.1 | 171.053 | 171.13 | 140.17 | 8 | 8 | 3030 | 5600 | BT1B617089B | 0.35 | 1.7 | 0.9 | 170 | 600 | 800 | ||||||

| 330.2 | 415.925 | 47.625 | 47.625 | 34.925 | 3.5 | 3.5 | 402 | 965 | BT1B440009 | 0.5 | 1.2 | 0.7 | 14.3 | 700 | 950 | ||||||

| 482.6 | 85.725 | 80.167 | 60.325 | 6.4 | 3.3 | 1210 | 2500 | EE526130/526190 | 0.4 | 1.5 | 0.8 | 48.5 | 630 | 850 | |||||||

| 333.375 | 469.9 | 90.488 | 90.488 | 71.438 | 6.4 | 3.3 | 1340 | 2850 | HM261049/HM261010 | 0.33 | 1.8 | 1 | 47 | 630 | 850 | ||||||

| Dimensions | Basic load | Designations | Calculated constant | Load | Mass | Limiting | |||||||||||||||

| ratings | factors | speeds | |||||||||||||||||||

| mm | kN | e | Y | Y0 | kg | r/min | |||||||||||||||

| d | D | T | B | C | r1、2min | r3、4min | Cr | Cor | fat | oil | |||||||||||

| 343.154 | 450.85 | 66.675 | 66.675 | 52.388 | 8.5 | 3.5 | 935 | 2200 | LM361649A/LM361610 | 0.35 | 1.7 | 0.9 | 28 | 670 | 900 | ||||||

| 346.075 | 488.95 | 95.25 | 95.25 | 74.612 | 6.4 | 3.3 | 1420 | 3150 | HM262749/HM262710 | 0.33 | 1.8 | 1 | 55 | 630 | 850 | ||||||

| 355.6 | 482.6 | 60.32 | 55.56 | 38.1 | 7 | 7 | 572 | 1200 | 431884A | 0.48 | 1.25 | 0.7 | 26.5 | 630 | 850 | ||||||

| 380.1 | 480 | 50 | 48.08 | 35.08 | 6 | 4 | 594 | 1500 | BT1B380-332420 | 0.5 | 1.2 | 0.7 | 20.5 | 600 | 800 | ||||||

| 384.175 | 546.1 | 104.775 | 104.775 | 82.55 | 6.4 | 6.4 | 1870 | 4150 | HM266449/HM266410 | 0.33 | 1.8 | 1 | 77 | 560 | 750 | ||||||

| 403.225 | 460.375 | 28.575 | 28.575 | 20.638 | 3.5 | 3.3 | 246 | 765 | LL566848/LL566810 | 0.4 | 1.5 | 0.8 | 6.7 | 600 | 800 | ||||||

| 406.4 | 508 | 61.912 | 61.912 | 47.625 | 3.3 | 3.3 | 825 | 2120 | L467549/L467510 | 0.37 | 1.6 | 0.9 | 26.5 | 560 | 750 | ||||||

| 574.675 | 76.2 | 67.866 | 50.8 | 6.8 | 3.3 | 935 | 2040 | EE285160/285226 | 0.5 | 1.2 | 0.7 | 53.5 | 530 | 700 | |||||||

| 762 | 180.975 | 161.925 | 107.95 | 12.7 | 12.7 | 3690 | 6100 | H969249/H969210 | 0.94 | 0.64 | 0.35 | 320 | 380 | 500 | |||||||

| 415.925 | 590.55 | 114.3 | 114.3 | 88.9 | 6.4 | 6.4 | 2120 | 4800 | M268749/M268710 | 0.33 | 1.8 | 1 | 120 | 500 | 670 | ||||||

| 430.212 | 603.25 | 76.2 | 73.025 | 50.8 | 6.4 | 6.4 | 1100 | 2320 | EE241693/242375 | 0.52 | 1.15 | 0.6 | 59 | 500 | 670 | ||||||

| 431.8 | 571.5 | 89.694 | 89.77 | 66.75 | 6.4 | 6.4 | 1450 | 3450 | BT1B328284/HA1 | 0.44 | 1.35 | 0.8 | 60 | 500 | 670 | ||||||

| 431.902 | 685.698 | 177.8 | 177.88 | 142.95 | 6.4 | 6.4 | 3910 | 8650 | BT1B332900 | 0.48 | 1.25 | 0.7 | 253 | 430 | 560 | ||||||

| 447.675 | 635 | 120.65 | 120.65 | 95.25 | 6.4 | 6.4 | 2380 | 5500 | M270749/M270710 | 0.33 | 1.8 | 1 | 120 | 450 | 600 | ||||||

| 457.2 | 573.088 | 74.612 | 74.612 | 57.15 | 6.4 | 6.4 | 1120 | 3000 | L570649/L570610 | 0.4 | 1.5 | 0.8 | 43.5 | 500 | 670 | ||||||

| 603.25 | 85.725 | 84.138 | 60.325 | 6.4 | 3.3 | 1450 | 3400 | LM770949/LM770910 | 0.46 | 1.3 | 0.7 | 61.5 | 480 | 630 | |||||||

| 615.95 | 85.725 | 85.725 | 66.675 | 6.4 | 6.4 | 1470 | 3800 | LM272235/LM272210 | 0.33 | 1.8 | 1 | 72 | 450 | 600 | |||||||

| 660.4 | 91.28 | 85.725 | 62.705 | 10.5 | 6.4 | 1790 | 3650 | EE737181/737260/VQ601 | 0.37 | 1.6 | 0.9 | 91 | 450 | 600 | |||||||

| 479.425 | 679.45 | 128.588 | 128.66 | 101.68 | 6.4 | 6.4 | 2750 | 6300 | BT1B332529/HA1 | 0.33 | 1.8 | 1 | 145 | 430 | 560 | ||||||

| 482.6 | 634.873 | 80.962 | 80.962 | 63.5 | 6.4 | 3.3 | 1470 | 3650 | EE243190/243250 | 0.35 | 1.7 | 0.9 | 67.5 | 450 | 600 | ||||||

| 498.399 | 634.873 | 80.962 | 80.962 | 63.5 | 6.4 | 3.3 | 1470 | 3650 | EE243196AX/243250 | 0.35 | 1.7 | 0.9 | 60 | 450 | 600 | ||||||

| 498.475 | 634.873 | 80.962 | 80.962 | 63.5 | 6.4 | 3.3 | 1470 | 3650 | EE243196/243250 | 0.35 | 1.7 | 0.9 | 60 | 450 | 600 | ||||||

| 498.653 | 634.873 | 80.962 | 80.962 | 63.5 | 6.4 | 3.3 | 1470 | 3650 | EE243196AS/243250 | 0.35 | 1.7 | 0.9 | 59.5 | 450 | 600 | ||||||

| 520.7 | 736.6 | 88.9 | 81.758 | 53.975 | 6.4 | 3.3 | 1650 | 3350 | EE982051/982900 | 0.48 | 1.25 | 0.7 | 100 | 400 | 530 | ||||||

| Dimensions | Basic load | Designations | Calculated constant | Load | Mass | Limiting | |||||||||||||||

| ratings | factors | speeds | |||||||||||||||||||

| mm | kN | e | Y | Y0 | kg | r/min | |||||||||||||||

| d | D | T | B | C | r1、2min | r3、4min | Cr | Cor | fat | oil | |||||||||||

| 536.575 | 761.873 | 146.05 | 146.05 | 114.3 | 6.4 | 6.4 | 3360 | 8000 | M276449/M276410 | 0.33 | 1.8 | 1 | 208 | 380 | 500 | ||||||

| 539.75 | 635 | 50.8 | 50.8 | 38.1 | 6.4 | 6.4 | 781 | 2160 | LL575349/LL575310 | 0.4 | 1.5 | 0.8 | 27 | 430 | 560 | ||||||

| 549.275 | 692.15 | 80.963 | 80.963 | 61.913 | 6.4 | 6.4 | 825 | 2120 | L476549/L476510 | 0.37 | 1.6 | 0.9 | 67 | 560 | 750 | ||||||

| 558.8 | 736.6 | 88.108 | 88.108 | 63.5 | 6.4 | 6.4 | 1830 | 4150 | EE843220/843290 | 0.35 | 1.7 | 0.9 | 92.5 | 380 | 500 | ||||||

| 736.6 | 104.775 | 104.775 | 80.962 | 6.4 | 6.4 | 2330 | 5700 | LM377449/LM377410 | 0.35 | 1.7 | 0.9 | 115 | 380 | 500 | |||||||

| 607.72 | 787.4 | 93.662 | 93.662 | 69.85 | 6.4 | 6.4 | 2160 | 5300 | EE649239/649310 | 0.37 | 1.6 | 0.9 | 110 | 340 | 450 | ||||||

| 609.6 | 787.4 | 93.662 | 93.662 | 69.85 | 6.4 | 6.4 | 2160 | 5300 | EE649240/649310 | 0.37 | 1.6 | 0.9 | 110 | 340 | 450 | ||||||

| 787.4 | 93.662 | 93.662 | 69.85 | 6.4 | 6.4 | 2160 | 5300 | EE649240AX/649310 | 0.37 | 1.6 | 0.9 | 110 | 340 | 450 | |||||||

| 660.4 | 812.8 | 95.25 | 95.25 | 73.025 | 6.4 | 6.4 | 1940 | 5600 | L281147/L281110 | 0.33 | 1.8 | 1 | 105 | 320 | 430 | ||||||

| 939.8 | 136.525 | 127.08 | 98.5 | 6.4 | 6.4 | 3740 | 8150 | 332383 | 0.4 | 1.5 | 0.8 | 287 | 280 | 380 | |||||||

| 1000 | 152.4 | 142.24 | 113.665 | 6.4 | 6.4 | 4400 | 9500 | BT1B334140/HA4 | 0.43 | 1.4 | 0.8 | 410 | 260 | 360 | |||||||

| 679.45 | 901.7 | 142.875 | 142.875 | 111.125 | 9.7 | 6.4 | 3580 | 9000 | LM281849/LM281810 | 0.33 | 1.8 | 1 | 242 | 280 | 380 | ||||||

| 682.625 | 965.2 | 185.738 | 185.81 | 142.95 | 6.4 | 6.4 | 5120 | 12500 | 332283 | 0.33 | 1.8 | 1 | 420 | 260 | 360 | ||||||

| 685.8 | 876.3 | 93.662 | 92.075 | 69.85 | 6.4 | 6.4 | 2120 | 5500 | EE655270/655345 | 0.43 | 1.4 | 0.8 | 130 | 300 | 400 | ||||||

| 711.2 | 939.8 | 120.65 | 115.38 | 73.33 | 6.4 | 6.4 | 2640 | 6200 | BT1B328068/HA4 | 0.75 | 0.8 | 0.45 | 206 | 240 | 340 | ||||||

| 723.9 | 914.4 | 84.138 | 80.962 | 60.325 | 5.5 | 6.4 | 2050 | 4900 | EE755285/755360 | 0.37 | 1.6 | 0.9 | 115 | 280 | 380 | ||||||

| 736.6 | 825.5 | 31.75 | 31.75 | 25.4 | 3.5 | 3.3 | 429 | 1370 | LL582949/LL582910B | 0.4 | 1.5 | 0.8 | 22.5 | 300 | 400 | ||||||

| 759.925 | 889 | 69.85 | 69.85 | 50.8 | 3.3 | 3.3 | 1230 | 3800 | LL483448/LL483418 | 0.37 | 1.6 | 0.9 | 67.5 | 280 | 380 | ||||||

| 889 | 88.9 | 88.9 | 72 | 3.3 | 3.3 | 1940 | 6200 | L183448/L183410 | 0.3 | 2 | 1.1 | 94 | 260 | 360 | |||||||

| 774.7 | 965.2 | 93.662 | 80.962 | 66.675 | 6.4 | 3.3 | 1940 | 4900 | EE752305/752380 | 0.4 | 1.5 | 0.8 | 131 | 240 | 340 | ||||||

| 801.688 | 914.4 | 58.738 | 58.738 | 41.275 | 3.5 | 3.3 | 1100 | 3550 | LL584449/LL584410 | 0.4 | 1.5 | 0.8 | 53.5 | 260 | 360 | ||||||

| 838.2 | 1041.4 | 93.662 | 88.9 | 66.675 | 6.4 | 6.4 | 1900 | 4800 | EE763330/763410 | 0.44 | 1.35 | 0.8 | 160 | 220 | 320 | ||||||

| 857.25 | 1092.2 | 120.65 | 111.125 | 76.2 | 19 | 6.4 | 2810 | 7350 | EE157337/157430 | 0.57 | 1.05 | 0.6 | 245 | 200 | 300 | ||||||

| 977.9 | 1130.3 | 66.675 | 63.5 | 47.625 | 6.4 | 6.4 | 1450 | 4400 | LL687949/LL687910 | 0.44 | 1.35 | 0.8 | 100 | 180 | 260 | ||||||

Address:No. 436, Longmen Avenue, Luolong District, Luoyang City, Henan Province, China

Tel:+86-13837910731 E-mail: sale@lyefinebearing.com Wechat : +86-13837910731